Introduction

Jackhammers are routinely used in construction and mining, when workers are required to remove layers of rock, concrete, or asphalt. However, these pneumatic drills are as dangerous as they are indispensable. To avoid accidents and long-term health issues, all employees should be properly trained prior to using a jackhammer.

Potential Hazards

The most common risks associated with jackhammer operations include:

Hand-Arm Vibration Syndrome.

Jackhammers can help workers dig into extremely hard materials, but the process is a violent one that often leads to repercussions on operators. For example, because operators must have a continuous and fast grip on the pneumatic drill, the vibrations generated by the latter can affect their health. Given enough exposure, workers begin to feel tingles and numbness in their hands and the fingers gradually turn white and cold due to poor blood circulation. In time, the condition develops into loss of grip and strength, while also becoming more painful and difficult to manage.Excessive Noise.

Jackhammers are extremely noisy machines that cannot be operated remotely. Employees who routinely handle or work around these tools are exposed to excessive noise that can eventually cause irreversible damage to the inner ear. Although most workers do not lose their hearing entirely, they nevertheless become unable to follow a regular conversation.Electrocution.

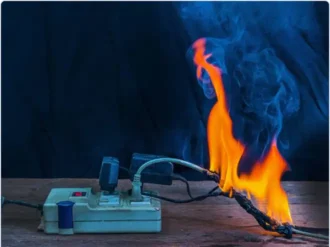

Jackhammer operators must always position the electric cord that powers the machine on one of their shoulders so as to prevent accidental damage to the cord. If the power supply loses its integrity, any worker who comes in direct contact with it can experience electrocution and burns. This endangers the safety of both the operator and nearby employees, especially if the damaged cord is not detected, reported, and replaced.Exposure to Hazardous Fumes and Substances.

Jackhammers are often used to remove layers of concrete and asphalt during road maintenance projects. As the operator drills into the latter, fumes, dust, and other hazardous substances become airborne and may be inhaled if proper equipment is not used. For example, although asbestos in no longer used in the construction of modern roads, this was not the case in the late 20th century, when it was one of the main ingredients in asphalt. Jackhammer operators who work on older roads may become exposed to airborne asbestos fibers, which can lead to asbestosis and even lung cancer.

Incident Prevention

Adequate safety training and the correct use and maintenance of personal protective equipment are two of the most important steps one can take towards incident prevention when operating a jackhammer. Many workers may not even be aware of the dangers posed by this tool, which means that they cannot possibly assess risks or effectively prevent accidents.

Personal protective equipment such as anti-vibration gloves can dampen some of the harmful effects that jackhammers have on operators, whereas noise-cancelling headphones or muffles should always be used to avoid long-term hearing problems. A water spray control system can minimize exposure to airborne dust, while respirators can be used to avoid exposure to hazardous substances such as asbestos.

It is essential that jackhammers are checked for adequacy prior to being used. Malfunctioning equipment can lead to electrocution and even the laceration of the operator’s hands, legs, or body. Finally, due avoid accidents caused by human error, as well as prolonged exposure to noise and vibrations, companies should institute strict shifts to rotate between workers who are assigned to jackhammer duties.

Recommended Safety Courses

What You Can Do to Stay Safe

If your job requires you to routinely operate a jackhammer, then you have the right to be informed about the dangers and long-term effects of this type of work. In Canada, your employer is under legal obligation to provide access to the necessary safety training for both you and your colleagues.

Operating a jackhammer may be a part of different jobs across several industries. These include:

- Driller or miner in the Oil & Gas industry.

- Driller or rigger in the Seismic industry.

- Miner, dryman, or driller in the Mining industry.

- Construction laborer or equipment operator in the Construction industry.

To consult a more comprehensive list of safety courses best suited for your line of work, please visit the corresponding industry page and navigate to your specific job.