Introduction

Aircraft maintenance employees perform crucial tasks for the Canadian transportation industry, from inspections to overhaul, repair, replacements, and compliance with airworthiness directives. The lives of passengers depend on the ability of these employees to work effectively, yet the job is often dangerous and can expose workers to a wide range of hazards.Potential Hazards

The most common risks associated with aircraft maintenance include:

Exposure to Carbon Monoxide and Other Dangerous Substances.

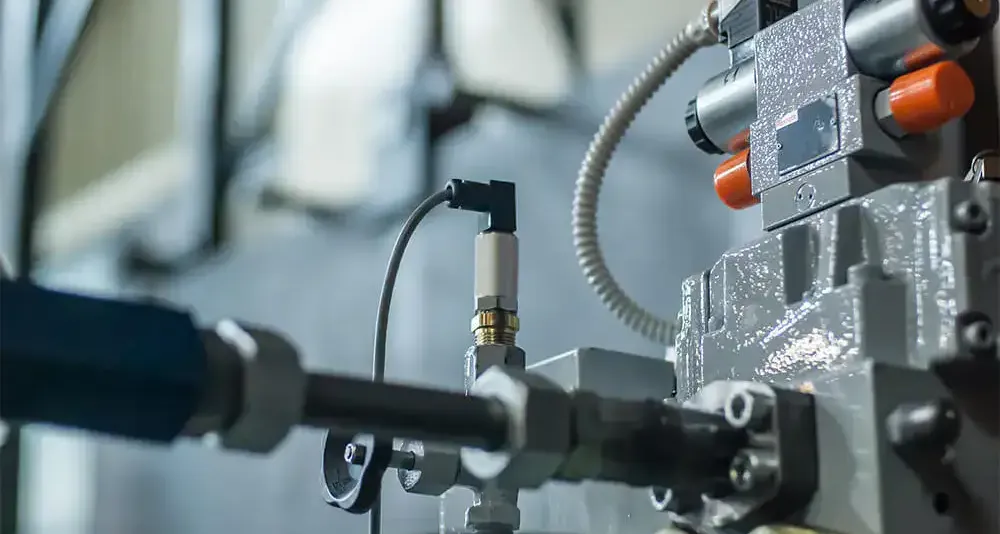

In aviation and especially in aircraft maintenance, Carbon Monoxide – a potentially deadly gas – is often found in exhaust from internal combustion engines, APU, and aircraft turbine engines. Without proper protection, employees who are exposed to high concentrations of CO can lose their lives, whereas those who inhale small amounts over an extended period of time may become severely ill. Furthermore, chemicals found in lubricating oils, hydraulic fluids, popular cleaning solvents, or adhesives can cause immediate irritation of the skin or impair respiratory function when inhaled.Lifting and Carrying Heavy Objects.

Aircraft maintenance employees are frequently required to lift heavy equipment and objects, such as, for example, the starter generator. The latter weighs approximately 80 lbs, which means that, if a worker lifts it incorrectly, the strain can lead to muscle or ligament damage and even cause a hernia. In addition, while these large objects are being moved, any wrong step can cause employees to drop the weight and potentially hurt themselves and/or other nearby colleagues.Excessive Noise.

The inspection and repair of aircraft takes place in a very noisy environment. If headphones or muffles are not used, prolonged exposure to this excessive noise can lead to the destruction of fine hairs in the inner ear. The damage is permanent and severe enough to make workers unable to follow a regular conversation.Working in Confined Spaces.

Entry in aircraft wings, fuel tanks, and other confined areas is part and parcel of aircraft maintenance work. Essential inspection and repair tasks must be carried out in these spaces, which means that the employee must be efficient in order to avoid errors. This, however, is made difficult by the nature of the space and an often-improper atmosphere. If done incorrectly, aircraft maintenance work in confined enclosures can lead to injury, as well as affect an employee’s efficiency and put thousands of future passengers at risk.

Incident Prevention

Two of the most important aspects of incident prevention in aircraft maintenance are rigorous safety training and personal protective equipment. Employees must first be made aware of the dangers they face during routine operations before they can learn to assess and avoid risks. An inspector who does not consider the hazards of lifting a heavy object, for example, may do so carelessly and thus injure him- or herself, as well as others.

At the same time, many of the work-related hazards in aircraft maintenance can be mitigated or avoided altogether with the correct use of personal protective equipment. Working safely around exhaust, for instance, requires the proper use of respirators, whereas most chemicals involved in cleaning and repair should only be handled by employees wearing gloves and full-bodied protective gear.

Companies must create the right work environment for aircraft maintenance specialists, especially since the lives of thousands of passengers may one day depend on the latter. When employees are required to enter confined spaces, for example, they should only do so after they have received extensive training and under close supervision. First aid equipment should be available on-site at all times in case of emergency.

Recommended Safety Courses

What You Can Do to Stay Safe

As an aircraft maintenance specialist, undergoing the necessary safety training to prepare for the hazards commonly associated with your line of work is the most efficient step you can take towards maintaining your safety and that of your colleagues. In Canada, your employer is required by law to provide access to the right safety courses as soon as you are hired.

For a comprehensive list of safety courses best suited for aircraft maintenance, please visit our Automotive and Manufacturing industry page.