Introduction

To ensure the continuous safety of visitors and hired personnel, rollercoasters must be inspected on a regular basis. Depending on the size of the theme park, maintenance technicians and ride attendants can make up entire departments. To avoid incidents, the latter must undergo comprehensive safety training design to help them identify and deal with the hazards associated with rollercoaster repair and maintenance.

Potential Hazards

Some of the most common risks associated with roller coaster repair and maintenance are:

Electric Shocks.

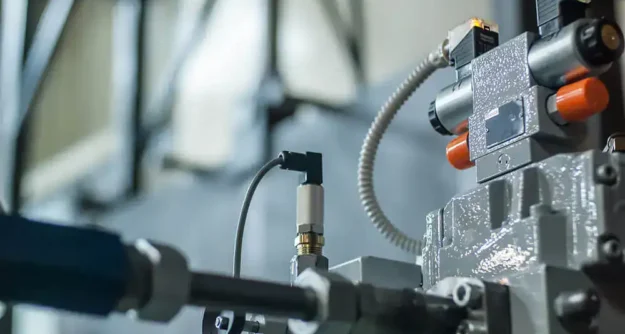

Every ride features a control panel that regulates the flow of electricity throughout the machinery. Before any hands-on maintenance work is performed, staff members must learn how to de-energize and lockout various components. This ensures that no ride movement takes place while technicians are inspecting the rails, but also that they will be protected from high voltages.Falls from Height.

High-stress areas of each ride are usually inspected on a daily basis. These include the underside of sizeable drops, as well as airtime hills. Particularly in the case of the latter, maintenance crews must use suspended access equipment (SAE) or cranes. Unfortunately, a significant portion of theme-park accidents are related to falling from dangerous heights.Crane Accidents

For more complex rides in large theme parks, SAE and personal protective equipment (PPE) might not be enough to reach suspended sections of the rails. In these instances, cranes and boom-supported platforms are used by maintenance personnel. Although the latter has a relatively small risk of injury, operator error is known to cause a fair number of accidents every year.First Aid Emergencies.

It is not unusual for both visitors and employees of a theme park to require first aid assistance. To ensure that everything is done to assist injured individuals, a course in first aid awareness is necessary.

Incident Prevention

Before any maintenance or repair activity is carried out, the entire rollercoaster or targeted sections must be completely locked out. The importance of this phase cannot be overstated, as there are numerous cases of employees being involved in unfortunate accidents or getting electrocuted due to hot circuitry on a yearly basis.

When verifying the structural integrity of the ride, employees tasked with maintenance are required perform meticulous tasks at heights. Workers must therefore undergo in-depth fall arrest training in order to become familiar with the suspended equipment which ensures their safety. While electrical and mechanical engineers don’t usually work at heights, they do have to look out for other risks.

Statistically speaking, accidents in theme parks are most often caused by human error. With the appropriate safety courses, the work hazards associated with rollercoaster repair and maintenance activities can be reduced and even completely avoided.

Recommended Safety Courses

What You Can Do to Stay Safe

All theme park employees have the right to be fully informed in terms of the risks associated with their jobs and it is the responsibility of the employer to guarantee that everyone who is hired undergoes safety training. The information provided by these safety courses makes it possible for workers to diminish the hazards associated with rollercoaster repair and maintenance.

To browse a comprehensive list of safety courses that might be required for rollercoaster repair and maintenance, please visit our Construction industry page.